Why Use Anodized Aluminum Diagrams?

Why Use Anodized Aluminum Diagrams? In the ever-evolving landscape of modern industry, precision and durability are paramount. At Laser.US, we understand the importance of providing solutions that not only meet but exceed the expectations of our clients. That’s why we advocate for the use of anodized aluminum diagrams, and in this essay, we’ll delve into the myriad benefits of incorporating this innovative material into your projects.

Why Use Anodized Aluminum Diagrams? Best for Heavy Duty Industrial Uses

First and foremost, let’s clarify what anodized aluminum is and why it stands out in the realm of industrial applications. Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum, resulting in a durable, corrosion-resistant surface. This process not only strengthens the material but also provides a smooth, aesthetically pleasing finish. By utilizing anodized aluminum in our diagrams, we ensure longevity and reliability, even in the most demanding environments.

Why Use Anodized Aluminum Diagrams? Strength

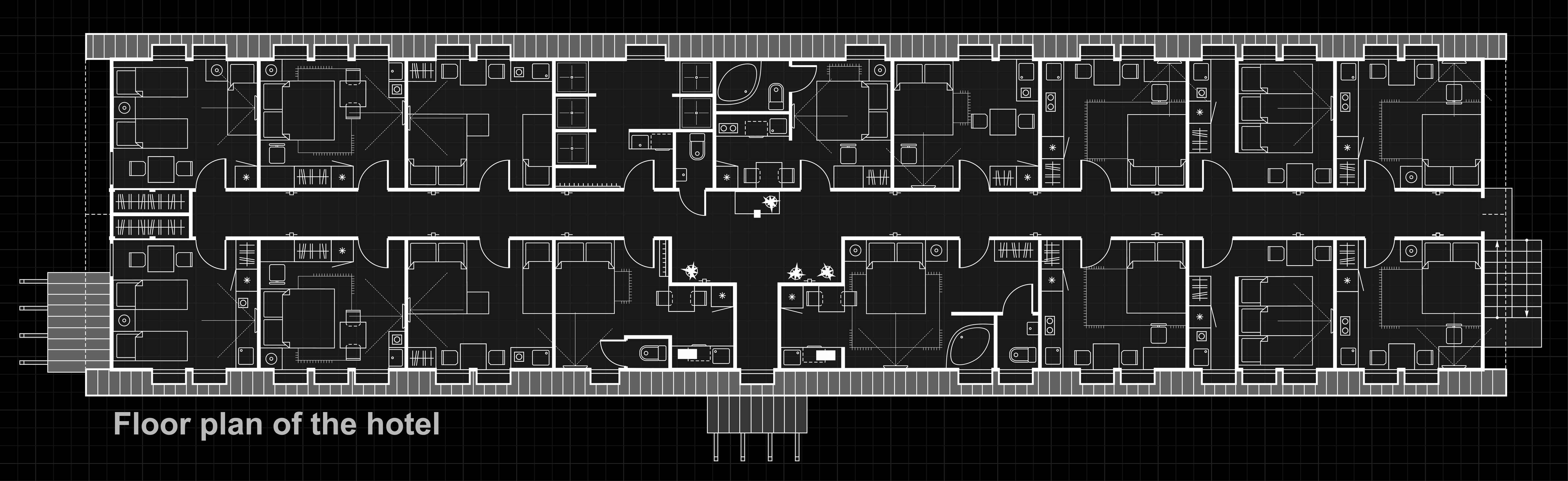

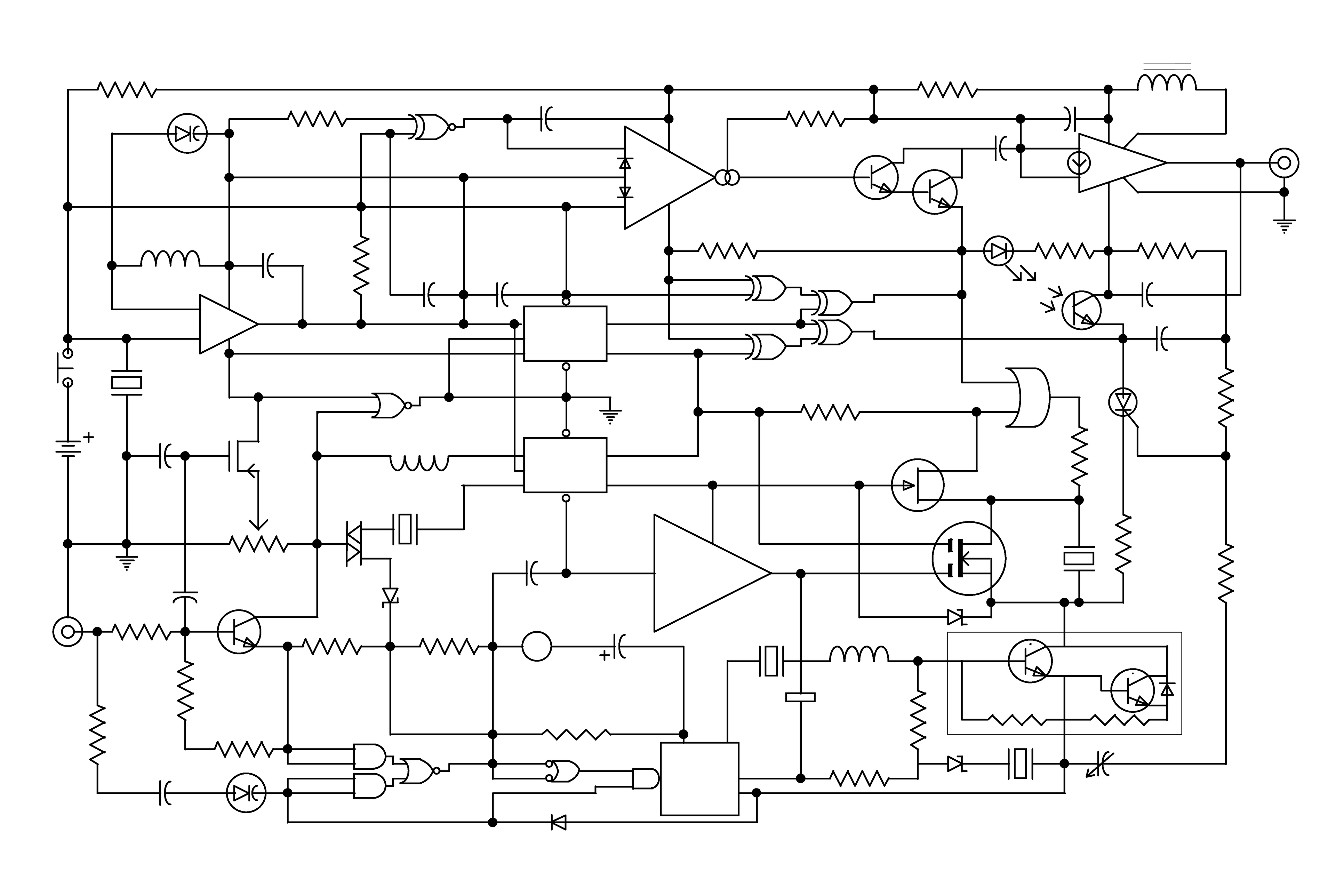

One of the primary advantages of anodized aluminum diagrams is their exceptional durability. Unlike traditional materials, such as plastic or paper, anodized aluminum is resistant to scratches, abrasions, and fading. This resilience makes our diagrams ideal for use in harsh conditions, including outdoor settings or industrial facilities where exposure to moisture, chemicals, or UV radiation is a concern. With Laser.US’s anodized aluminum diagrams, you can trust that your critical information will remain intact and legible for years to come.

Why Use Anodized Aluminum Diagrams? Customization

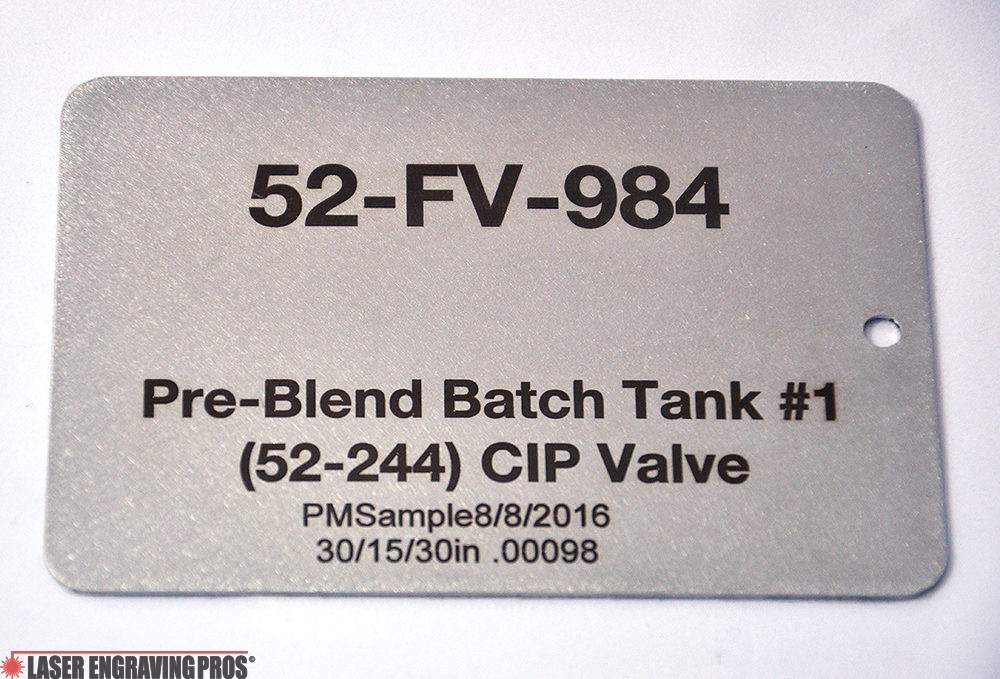

Furthermore, anodized aluminum offers unparalleled versatility, allowing for precise customization to meet the unique requirements of each project. Through our advanced laser marking technology, we can create detailed diagrams with pinpoint accuracy, ensuring clarity and readability, even in the smallest of details. Whether you need intricate schematics, instructional diagrams, or identification labels, Laser.US can deliver solutions tailored to your exact specifications.

Why Use Anodized Aluminum Diagrams? Sustainability

In addition to its durability and versatility, anodized aluminum boasts environmental benefits that align with our commitment to sustainability. Unlike many other materials used in diagram production, aluminum is fully recyclable, minimizing waste and reducing our carbon footprint. By choosing Laser.US’s anodized aluminum diagrams, you’re not only investing in quality and reliability but also contributing to a greener, more sustainable future.

Why Use Anodized Aluminum Diagrams? Cost Effective

Another compelling reason to use anodized aluminum diagrams is their cost-effectiveness over the long term. While the initial investment may be slightly higher than traditional materials, the durability and longevity of anodized aluminum ultimately result in significant savings. With minimal maintenance requirements and resistance to wear and tear, our diagrams offer a superior return on investment, ensuring continued performance and value for years to come.

Safety and Compliance

Moreover, anodized aluminum diagrams provide enhanced safety and compliance benefits, particularly in regulated industries such as aerospace, automotive, and manufacturing. The corrosion-resistant properties of aluminum ensure that critical information remains intact, reducing the risk of errors or accidents due to damaged or illegible diagrams. Additionally, our laser marking process produces high-contrast, permanent markings that meet stringent industry standards for clarity and accuracy.

The use of anodized aluminum diagrams offers a multitude of advantages that make them the optimal choice for modern industrial applications. From unparalleled durability and versatility to environmental sustainability and cost-effectiveness, Laser.US’s anodized aluminum diagrams are designed to exceed your expectations in every way. Whether you’re looking to enhance safety, streamline operations, or simply improve the longevity of your equipment, trust Laser.US to deliver superior solutions that stand the test of time.

– CONTACT LASER.US –

(800) 482-1553

Monday – Friday

9am – 5pm EST

Check out our Sister Sites:

Laserengravingpros.com

Lasercuttingpros.net

Engravedswitchplatesnow.com

Metaltagmaker.com