Black Satin Anodized Aluminum

Black Satin Anodized Aluminum is one of the most commonly used metals in our society. It is an element commonly found in the earth’s crust. Aluminum occurs in clays and in various mineral forms that are obtained from bauxite ore through electrolysis. It is widely used in structural and architectural buildings. A fantastic material that can be cast, rolled or machined into almost any shape. Aluminum is also extremely resistant to weathering thanks to its natural reaction with oxygen, which creates a non-porous oxide layer on the surface. This layer protects the material from rust and corrosion. Aluminum can also be anodized, where the oxide layer is electrochemically controlled to produce a satin finish, or dyes can be added to further improve the appearance and durability of the aluminum. Clear satin aluminum anodization is one of the most popular surface treatments for aluminum profiles manufactured for many industries where aesthetics, durability and easy maintenance are required.

Anodized aluminum finishes have made aluminum one of the most respected and widely used materials in the manufacture of consumer, industrial and commercial products. Anodizing provides an attractive, low-maintenance, highly durable and long-lasting material for exterior applications, roofs, curtain walls, cladding, windows and doors. Not only can aluminum be anodized to create a clear, satin finish, but this process can also be performed to create a selection of different colors and shades.

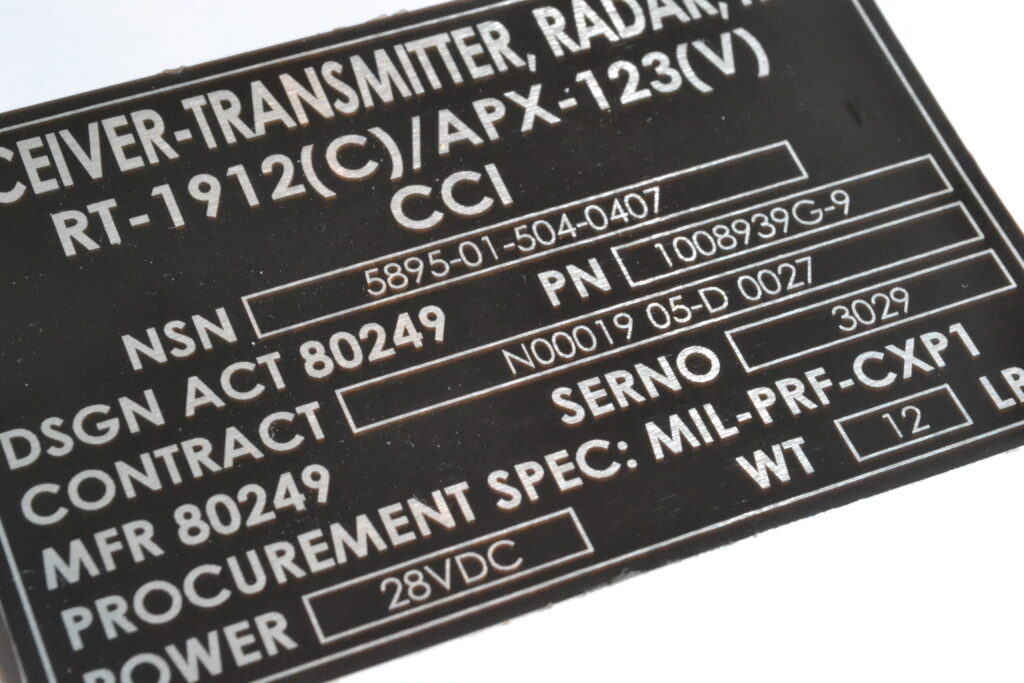

Here at Laser.us we hold Quality to a high mark, so we ensure our materials are of the best quality for your Labeling for Data Centers & IT Equipment. In a technologically demanding world, the data center is the most crucial component to insure “the lights stay on”. If you require Black Satin Anodized Aluminum – You came to the right place. Simply fill out the RFQ form below and one of our team-members will reach out as soon as possible. We don’t ask for much information, just the basics to get started on sending you an estimate. We understand how valuable your time is and we have stream-lined the process of design, manufacturing and fulfillment. Let us help you build your data center.

Anodization is an electrochemical process that increases the transparent thickness of a passive, natural protective surface layer of aluminum oxide. Aluminum oxide is not applied to the surface like paint or coating, but is part of the surface structure and therefore cannot chip or flake. The anodization process begins by dipping aluminum into an acidic electrolyte bath and passing an electric current through the medium. The cathode is mounted in the anodized tank, the aluminum acts as an anode, then oxygen ions are released from the electrolyte and combine with the aluminum atoms on the surface of the anodized part. During a tightly controlled oxidation process called anodization, a layer of oxide electrochemically grows on the surface of the aluminum.

Why Lasers are the Future ?

Unlike traditional hand techniques, the intricacy, speed, and cost-effective nature of laser engraving has made it a popular method for businesses needing to personalize large volumes of Labels and Plates for Data Centers & IT Equipment with a consistent result over-all. Laser engraving labels requires careful consideration of the materials properties and refine the laser to the strict parameters to achieve the desired results. Luckily over the years we have perfected our engraving techniques across various material types and popular brands!

– CONTACT US –

(800) 482-1553

Monday – Friday 9am – 5pm EST.