PIA Process for Motherboards

PIA Process for Motherboards at Laser.US! We understand that the motherboard is the heart of any computing device, providing the essential circuitry that allows the processor, memory, and all other components to communicate effectively. Ensuring the highest quality and performance of these critical components is our top priority. That’s why we employ the PIA process for motherboards, a meticulous and comprehensive approach to production, inspection, and assurance that sets our products apart in the industry. Here’s an in-depth look at our PIA process and why it makes a significant difference.

Precision Manufacturing

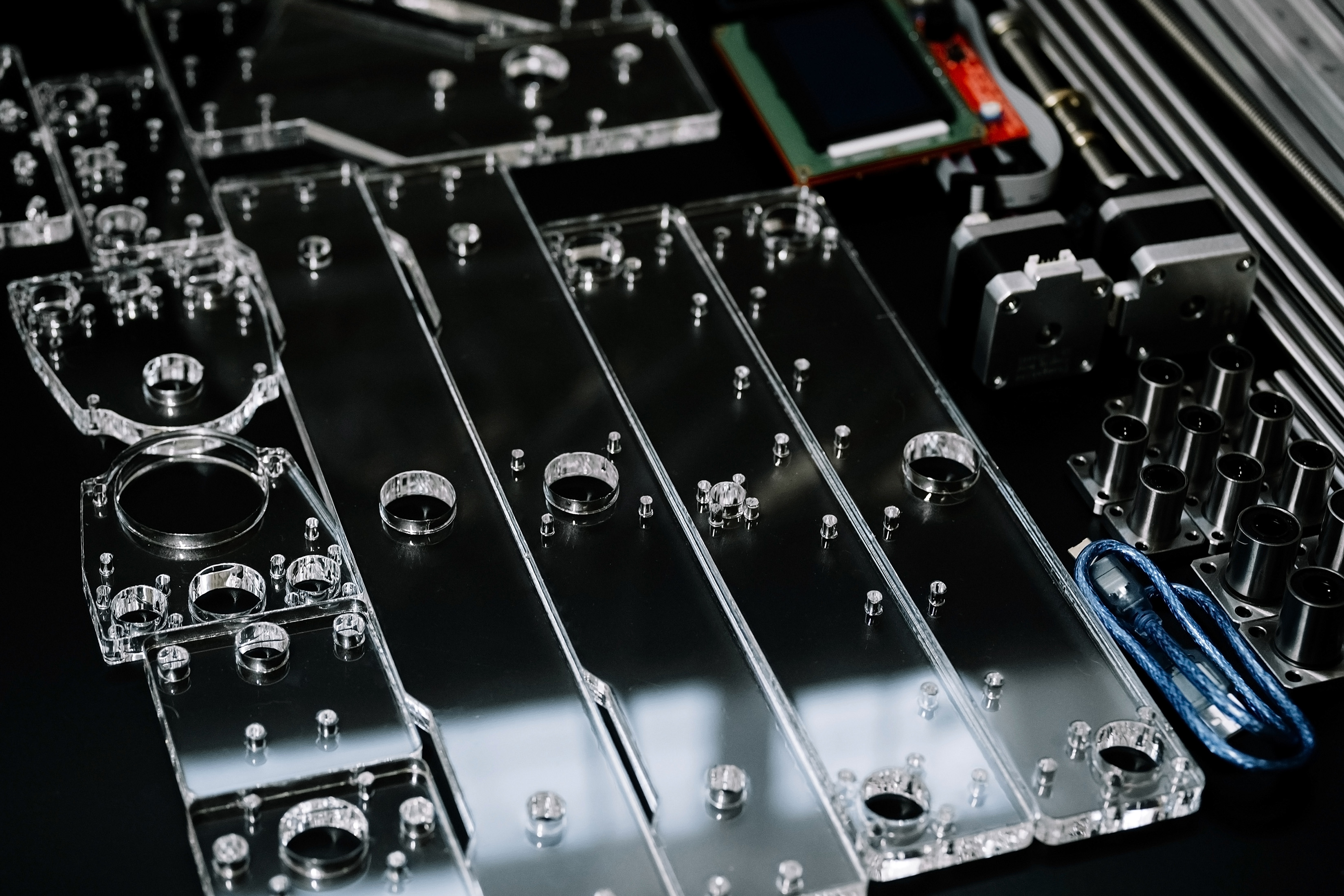

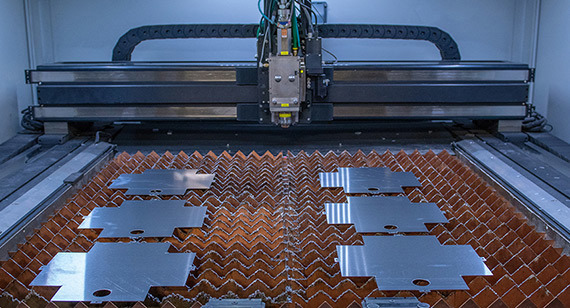

The PIA process begins with precision manufacturing, the cornerstone of producing high-performance motherboards. Our state-of-the-art facilities utilize cutting-edge technology and machinery to ensure each motherboard is constructed with the utmost accuracy. From the initial design phase to the final assembly, every step is carefully monitored and controlled.

We use advanced automated systems to handle the intricate soldering and component placement required for modern motherboards. These systems not only enhance precision but also increase production speed, allowing us to meet high demand without compromising on quality. Our commitment to precision manufacturing ensures that each motherboard we produce meets the exact specifications required for optimal performance.

PIA Process for Motherboards – Inspection at Every Stage

Inspection is a critical component of our PIA process. At Laser.US, we believe in catching and addressing potential issues early in the production process to prevent defects and ensure the highest quality end product. Our inspection protocol involves multiple stages of thorough checks and balances.

Incoming Inspection

Before any materials enter our production line, they undergo a rigorous incoming inspection. This step ensures that all components and raw materials meet our stringent quality standards. We check for consistency, purity, and compliance with industry specifications. By verifying the quality of our materials upfront, we lay a strong foundation for the entire manufacturing process.

PIA Process for Motherboards In-Process Inspection

As motherboards move through the production line, we perform in-process inspections at various critical stages. This continuous monitoring helps us identify and correct any issues immediately, maintaining the integrity of the manufacturing process. Our team of skilled technicians uses advanced diagnostic tools and techniques to verify that each component is correctly installed and functioning as intended.

Final Inspection

Before any motherboard leaves our facility, it undergoes a final comprehensive inspection. This includes visual examinations, functionality tests, and performance assessments to ensure that every unit meets our high standards. We test for electrical integrity, signal quality, and overall system performance. Only motherboards that pass this rigorous final inspection are approved for shipment.

PIA Process for Motherboards – Assurance of Quality and Reliability

Quality assurance is integral to our PIA process. At Laser.US, we implement a robust quality management system that complies with international standards. Our dedication to quality assurance is reflected in every aspect of our operations, from employee training to continuous process improvement.

Employee Training

Our employees are our most valuable asset, and we invest heavily in their training and development. Each team member receives comprehensive training on our PIA process, quality standards, and industry best practices. This ensures that everyone involved in the production process is equipped with the knowledge and skills necessary to maintain our high standards.

PIA Process for Motherboards has Continuous Improvement

We are committed to continuous improvement in all areas of our operations. By regularly reviewing and refining our processes, we strive to enhance efficiency, reduce waste, and improve product quality. Our continuous improvement initiatives include regular audits, feedback loops, and performance metrics to identify areas for enhancement.

Customer Feedback

Customer feedback is a crucial element of our quality assurance strategy. We actively seek input from our customers to understand their needs and expectations better. This feedback helps us identify potential areas for improvement and drives our efforts to exceed customer satisfaction. By listening to our customers, we ensure that our products not only meet but exceed market demands.

PIA Process for Motherboards from Laser.US, When You Need the Best!

At Laser.US, the PIA process for motherboards represents our unwavering commitment to precision, inspection, and assurance. By integrating advanced technology, rigorous inspection protocols, and a robust quality assurance system, we produce motherboards that deliver exceptional performance, reliability, and durability.

Choosing our motherboards means investing in products that embody quality at every stage of production. Our PIA process guarantees that each motherboard not only meets but surpasses industry standards, providing you with the confidence that your computing devices will perform at their best. Trust Laser.US for your motherboard needs and experience the superior quality that comes from a process dedicated to excellence.