T5052 Series Aluminum

On the hunt for Custom T5052 Series Aluminum Products? We are the company you have been looking for. You’re speaking with the Laser.us! If quality is what you’re looking for then you are in the right place. We are the “go-to” source for supplying all of your needs and we ship across the US via UPS each and every business day. Your Custom T5052 Series Aluminum Products will be accurate, cost-effective, and designed to spec to meet the needs of the client. Create an Organized, Easy to Navigate System with us here at Laser.us!

Why are we the BEST at producing Custom T5052 Series Aluminum Products ?

Here at Laser.US we hold Quality to a high mark, so we ensure our materials are of the best quality for your Labeling for Data Centers & IT Equipment. In a technologically demanding world, the data center is the most crucial component to insure “the lights stay on”. If you require T5052 Series Aluminum – You came to the right place. Simply fill out the RFQ form below and one of our team-members will reach out as soon as possible. We don’t ask for much information, just the basics to get started on sending you an estimate. We understand how valuable your time is and we have stream-lined the process of design, manufacturing and fulfillment. Let us help you build your data center.

Precision Engraving, Endless Tracking Possibilities.

As the proud owner of our engraving business, we leverage top-tier processing software to seamlessly integrate data into our advanced engraving systems. Our meticulous process not only eradicates spelling and informational errors but also eliminates the need for additional make-up plates. We prioritize precision, and before moving forward, we ensure your satisfaction by sending a proof for your approval. In our commitment to excellence, we provide a virtual mockup showcasing the placement and engraving details for each plate, granting you peace of mind that it will be executed flawlessly on the first attempt. Our dedication to quality is further demonstrated through our specially designed equipment tailored for switch plate engraving.

We Provide Direct-to-Consumer Shipping!

We aren’t the middle men in manufacturing, we are the man, meaning when you work with us, you’re working directly with the team producing your products.

We Do So Much More, It’s Not Even All Listed Here!

To further illustrate our passion for the craft, we established EngravingSwitchplates.com, a blog exclusively dedicated to our engraved device covers. Explore the array of options we offer, including Custom Wall Plates, GFI Plates, Switch Plates, Double-Gang Switch Plates, Single Gang-Switch Plates, and virtually any receptacle plate imaginable. If a particular design is unavailable, we can likely have it manufactured to meet your unique requirements. In instances where custom switch plates with specific cut-outs, holes, or squares are needed, count on us for precision engraving. We even offer the option to paint-fill your switch plates. With a commitment to efficiency, we guarantee a quick turnaround when you need it. Choose us for a seamless and reliable engraving experience!

Typical applications include marine, aircraft, architecture, general sheet metal work, heat exchangers, fuel lines and tanks, flooring panels, streetlights, appliances, rivets and wire. The exceptional corrosion resistance of 5052 alloy against seawater and salt spray makes it a primary candidate for the failure-sensitive large marine structures, like tanks of liquefied natural gas tankers.

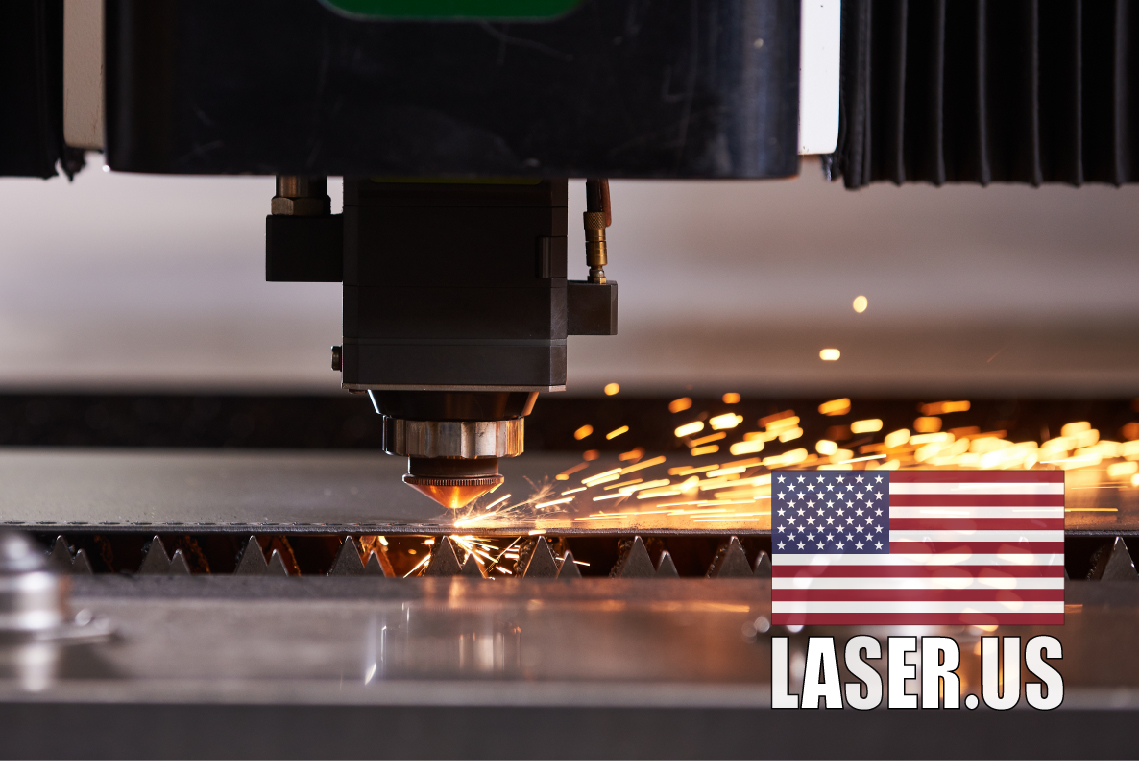

Customized metal mastery: Laser-cutting, engraving, and bending expertise.

Aluminum can be manufactured in more variety than almost any other metal in the industry. People in the architectural and industrial industries seem most interested in aluminum because of its inherent combination of being both lightweight and durable. There are 7 different alloys commonly used in aluminum manufacturing. Each series starts with a number 1-7 (1xxx, 2xxx, 3xxx, 4xxx, 5xxx, 6xxx & 7xxx). That number basically determines what alloying element has been added to the aluminum. 6000 Series is mixed with magnesium and silicone and used predominately in the form of extrusions and structural components like angles, beams and tubes. The most common aluminum used in the general fabrication industry is 3000, 5000 or 6000 series alloys.

We have T5052 Series Aluminum !!

It is important for engineers and architects to have a good understanding of the different types of aluminum welding and fabrication, as well as its many alloys, when ordering a specific type for a project. For example, when it comes to 6000 series aluminum, engineers often need 6061-T6 aluminum. This type of aluminum alloy has high tensile strength, but is also quite brittle. Therefore, it may meet the tensile requirements of a designed part, but fail when the part is to be formed or manufactured because the metal breaks at the bend line.

Due to the problem of fracturing, fabricated aluminum, such as those used in wall panels, general industrial manufacturing, etc., is best made with 5000 series aluminum, which is very easy to shape (without cracks or crazing), but also has a reliable tensile strength. In many cases, aluminum profiles such as aluminum angles, tubes or beams can be used in combination with flat sheet materials, in which case the alloys are not exactly the same. In these cases, manufacturers must ensure that welding consumables are carefully selected and suitable for both alloys. For example, 6000 series aluminum should not be welded to 3000 series filler metals.

Let Us Help with Your Next Fabrication!

Since laser cutting is a flexible process, playing with laser beams is our passion and specialty. We are able to laser-cut, laser-etch and laser-engrave anything you put your mind to. Creativity and originality drive us to create laser-cut metal parts, no order to big nor to small. When considering laser cutting metal parts, there are endless possibilities to choose from; missing metal parts, metal designs, metal nameplates, metal tags, keys, and more! That is why laser cutting is such a versatile process. Who the hell said metal is too hard to laser-cut?! On the contrary, if you compare with other methods, laser-cut metal parts are one of the most precise, efficient and unproblematic processes.We can laser-cut anything you can dream of: custom metal parts in tags, images, nameplates, marks, etc.

Let us help you build your Data Center.

Why Lasers are the Future ?

Unlike traditional hand techniques, the intricacy, speed, and cost-effective nature of laser engraving has made it a popular method for businesses needing to personalize large volumes of Labels and Plates for Data Centers & IT Equipment with a consistent result over-all. Laser engraving labels requires careful consideration of the materials properties and refine the laser to the strict parameters to achieve the desired results. Luckily over the years we have perfected our engraving techniques across various material types and popular brands!

– CONTACT US –

(800) 482-1553

Talk to a REAL PERSON:

Monday – Friday – 9:00 am – 5:00 pm

– OR –

Email Us Here!

Metal Fabrications & Other Laser Enterprises:

Metaltagmaker.com

Lasercuttingpros.net

Engravedswitchplatesnow.com

Laserengravingpros.com